Aiming to do long term cooperation with all of our partners, quality control is the soul to ensure we are supplying the correct products we promise. That’s why we specially set a QC department to do quality control and guarantee the quality of products we provide. It melts through each production procedures: drilling, assembling, forming, packaging, loading…

Through customer reviews, we create a transparent and trustworthy brand image. These reviews not only provide our customers with real-world experiences and insights, but also help our customers make informed purchasing decisions.

Laboratory not only provide our R&D staff with the infrastructure to develop new products, conduct experiments and advance knowledge in their respective fields, but also ensure that our products meet regulatory and quality standards through rigorous testing.

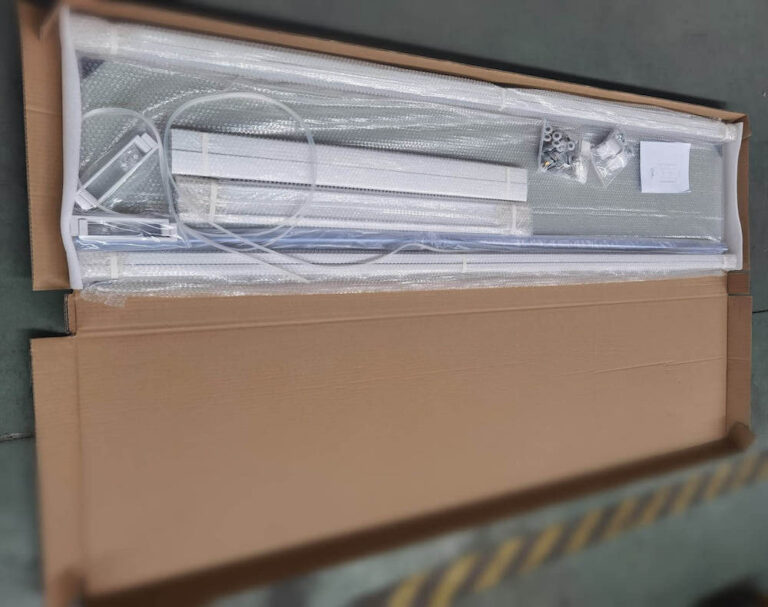

This part’s inspection is very important, more formal and easily get whole workshop nervous, as we may require to re-work all if inspection fail. It’s untolerant and must unpack each box and check one by one if our inspectors find wrong accessory packed inside or aluminum profile and glass not match well, or other serious defection.

Whether the final inspection result is fail or pass, our quality department manager will issue a copy of inspection report, written in English. We record all the problems and issues as it is, the report will be shared not only with our customer, but also kept as important documentory for ourselves records.

Three years long pandemic make the global economy more difficult. We understand price are very sensitive for more and more markets now, so we try our best to offer the lowest price while with better quality, to make it a balance and even competitive while safeguarding decent quality level, that’s why our team exsit.